-

EN877 SML Hubless Cast Iron Pipe

I-SML no-hub cast iron drainage amapayipi nokufakwa kuhlangabezana nezinga le-BSEN877, DIN19522, ISO6594.Izinto ezisetshenziswayo ziyakwazi ukuphinda zisetshenziswe ngo-100% futhi zigaywe kabusha, futhi zidlulisa umsindo ophansi, ubufakazi bomlilo, ubufakazi bokuvuza kanye ne-anti-corrosion.Asetshenziswa kakhulu ukukhipha amanzi ezakhiweni, i-drainage, imfucuza kanye ne-vent.Futhi uhlelo lwamanzi emvula olufakwe ngaphandle kwezakhiwo kanye nesistimu engcwatshwe ngaphansi komhlaba ingahlinzekwa.

Amapayipi e-EN877 angaphandle abomvu, i-epoxy enogqinsi olungekho ngaphansi kwama-70um.Ngaphakathi uqweqwe lwe-epoxy resin enogqinsi oluyi-120um.Noma ngaphakathi nangaphandle kukhona ngaphezu kwe-120μm powder epoxy coating enombala obomvu.

Izinto ezifakwayo nazo zibomvu ngaphakathi nangaphandle, i-liquid epoxy resin ingaphezu kuka-70um, kanti i-powder epoxy ingaphezu kuka-120um obukhulu.

-

EN877 BML Hubless Cast Iron Pipe

Amapayipi okukhipha amanzi e-BML awohlelo lokudonsa amanzi ebhulohweni.

Ukumboza kwangaphandle: Amapayipi e-BML afaka isifutho se-zinc esingugqinsi okungenani esingu-40um (290g/㎡), ngaphezu kwalokho kuzofafaza i-epoxy resin esiliva empunga okungenani engu-80um.

I-coating yangaphakathi ifana ne-epoxy resin engu-120um efana nepayipi le-SML.

-

EN877 KML Hubless Cast Iron Pipe

Ipayipi lokudonsa amanzi le-KML kanye nokufakwa kusetshenziselwa amanzi angcolile anagrisi emakhishini ochwepheshe kanye nezinsiza ezifanayo.

Ukumboza ngaphandle: Faka i-zinc yokufutha enobukhulu bendawo obungu-min 130g/㎡, futhi ngaphezu kwalokho isembozo se-epoxy okungenani esingu-70um.

I-coating yangaphakathi ine-epoxy enombala we-orche.Ungqimba oluphindwe kabili lwe-resin epoxy enogqinsi lwesendlalelo esingu-240um.

Ukufakwa kwe-KML kuhlanganiswe ngaphakathi nangaphandle ngempushana yekhwalithi ephezulu engu-120um okungenani.

-

EN877 TML Hubless Cast Iron Pipe

Amapayipi okukhipha amanzi e-TML asekelwe ku-EN 877, ukuthi ukusetshenziswa kwamapayipi e-SML ukufakwa ngaphansi komhlaba.

Ukumboza kwangaphandle: Amapayipi e-TML afaka isifutho se-zinc esinobuningi obungu-130g/㎡, phezu kwalokho kunejazi lekhava elinsundu noma elibomvu.

I-Inside coating: I-coating ingumbala we-orche, i-epoxy 120um.

Ukufakwa: I-epoxy powder coating ebomvu, 120um okungenani.

-

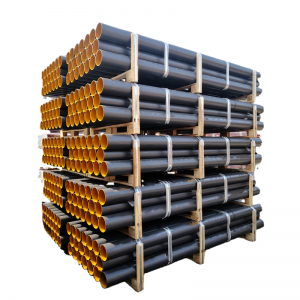

I-EN877 KML amaphakeji wepayipi lensimbi elisansimbi

Ipayipi lokudonsa amanzi le-KML kanye nokufakwa kusetshenziselwa amanzi angcolile anagrisi emakhishini ochwepheshe kanye nezinsiza ezifanayo.

Ukumboza ngaphandle: Faka i-zinc yokufutha enobukhulu bendawo obungu-min 130g/㎡, futhi ngaphezu kwalokho isembozo se-epoxy okungenani esingu-70um.

I-coating yangaphakathi ine-epoxy enombala we-orche.Ungqimba oluphindwe kabili lwe-resin epoxy enogqinsi lwesendlalelo esingu-240um.

Ukufakwa kwe-KML kuhlanganiswe ngaphakathi nangaphandle ngempushana yekhwalithi ephezulu engu-120um okungenani.

- Ukusekelwa kwe-imeyili plumbingsales01@sjzmetal-electric.com

- Shayela Ukusekela 0086-13833199589

0086-311-86031515